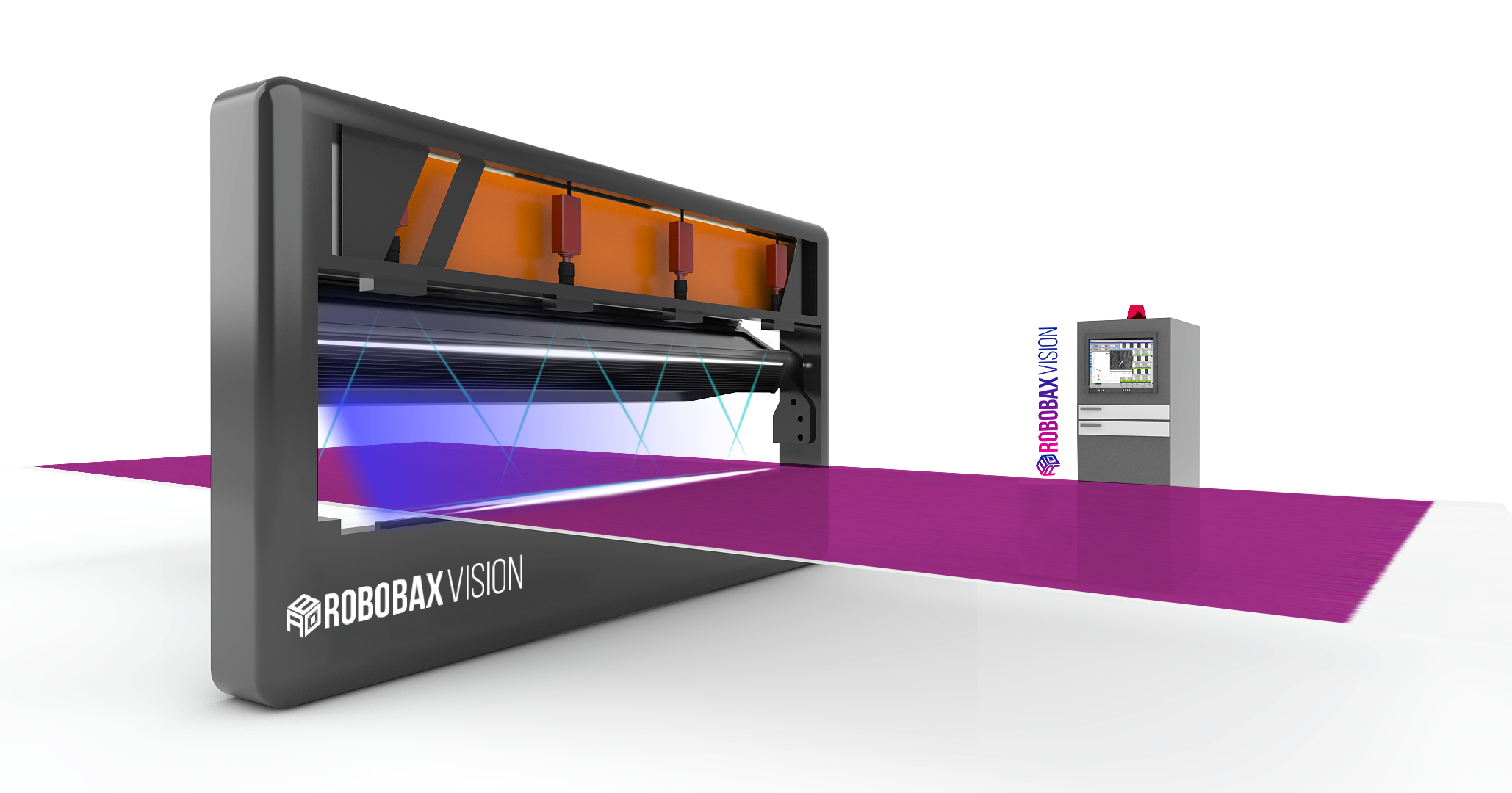

On the 3200mm wide mercerizing line, where we have integrated the artificial intelligence-supported camera vision system, it enables the detection of errors such as holes, tears, dirt, fold marks, etc. on the fabric where the process is applied. For example, the tensioning needles would break from time to time and remain stuck on the drum on the line. For this reason, while passing over the drum, the needle stuck in the drum caused continuous puncturing on the fabric due to the needle stuck in the drum, causing waste damage.

In the old manual quality controls, the problem could only be noticed approximately 9000 meters after the occurrence of the problem because the fabric, whose production was completed, was taken into the quality control process after the dock winding. In this process, since the process continued on the line, there was no instant information flow, causing the amount of waste to be too high.

In a fabric that passes through a mercerization line or a washing line at a speed of approximately 70 meters/minute, it is not possible to see a 0.046 square millimeter continuous hole error with manual control based on the human factor. However, with this integrated artificial intelligence-supported camera vision system that we have designed, these errors can be detected very easily and easily on a 24/7 basis.

With the system we have developed, such errors are immediately prevented and the continuation of the error and the growth of the damage is immediately prevented. Thus, since the ongoing process on the line is controlled instantly and in real time, the necessary intervention can be made immediately.